Chapter 8: Brush Control

Chapter 8: Brush Control thompsbb

One of the most visible outcomes of integrated roadside vegetation management (IRVM) is roadsides with sparse brush and trees. Brush control also has strong public support, although some residents may be concerned about removing brush and trees in the right-of-way. Many residents value trees and shrubs that provide suitable wildlife habitat and serve as windbreaks. Roadside managers can ease concerns by emphasizing the safety benefits of removing woody vegetation near roadsides.

Woody vegetation that is overgrown and close to the road poses a safety hazard for vehicles that enter the roadside during an accident. According to the Federal Highway Administration, trees larger than 4 inches in diameter at maturity pose safety issues for errant vehicles. Trees near sites where accidents occur more often, such as curves and intersections, may also need to be removed. Other reasons for removing trees and shrubs include:

- Motorists will have unobstructed lines of sight.

- Motorists will be able to see traffic signs.

- Shade will be reduced in crucial spots, allowing sunlight to melt ice on the pavement.

- Tree limbs that encroach on the road will be removed. When trees on private property have limbs hanging over the road, landowners may be contacted about removing the limbs or trees.

- Snow drifting caused by woody vegetation trapping snow will be reduced.

- Woody species on Iowa’s noxious weed list will be removed (see “Chapter 58, Noxious Weeds,” in the Iowa Administrative Code for the most updated list of noxious weeds).

- Shade reduction will allow prairie species planted in the roadside that require full sunlight to grow.

In 2002, the Iowa Highway Research Board, the Iowa Department of Transportation, and the Iowa Roadside Management Office at the University of Northern Iowa released “Tree and Brush Control For County Road Right-of-Way.” The report summarized the results of interviews with county engineers, roadside managers, and others to describe roadside tree and brush control methods used in Iowa counties. Information from the report and county and city IRVM plans formed the foundation of this chapter. See Appendix 8A for examples of brush control policies from IRVM plans.

Scope of Brush Control Within the Right-of-Way

Scope of Brush Control Within the Right-of-Way thompsbbSeveral IRVM plans state that all woody vegetation in the right-of-way is subject to removal unless otherwise directed by the engineer. Some counties list exceptions to woody vegetation removal. For example, Linn County’s IRVM plan (available at the Living Roadway Trust Fund website) includes a provision that some brush and trees may remain undisturbed in the right-of-way under the following conditions:

- The vegetation’s proximity to existing private fences or other structures prevents removal without causing damage to private property.

- The vegetation is located on or behind non-traversable back slopes and banks.

- The vegetation is located a safe distance away from the guardrail.

- The vegetation is located more than 30 feet away from the road.

Within the right-of-way, the priorities for brush removal can vary. For example, some counties prioritize controlling brush near the edge of the road, down the foreslope, and in the ditch bottom. Brush in these areas where errant vehicles are most likely to enter the roadside poses the greatest safety risk.

Other counties prioritize brush removal depending on the type of road. For example, near hard-surface roads with high traffic volumes, the county removes brush from the edge of the road to the ditch bottom. Near Level B roads (those that receive minimal maintenance) and dirt roads, which have low traffic volumes, the county does not prioritize brush cutting or mowing unless the trees and limbs contact vehicles on the road.

Timing of Brush Control

Timing of Brush Control thompsbb

Most brush control occurs during winter, which is the most effective time to employ many of the chemical and mechanical brush control methods to kill woody vegetation. Roadside managers and their assistants also have more time to dedicate to brush control, unlike during the growing season, when they are busy managing herbaceous vegetation.

Some IRVM plans leave the timing of brush control open-ended. It may vary according to staff and resource availability or the danger and sight impairment posed by trees and shrubs in the right-of-way.

Protecting Endangered Bat Habitat

The Indiana bat (Myotis sodalis), the northern long-eared bat (Myotis septentrionalis), and the tricolored bat (Perimyotis subflavus) are listed as endangered under the federal Endangered Species Act. This designation provides protection for their habitat, which includes forested areas of large portions of Iowa during the growing season. As determined by the U.S. Fish and Wildlife Service, suitable habitat for these species includes forests containing live trees or snags equal to or greater than 5 inches in diameter at breast height (dbh) with cracks, crevices, or hollows. These trees can occur in linear settings such as fencerows and are considered suitable habitats if located within 1,000 feet of other forested or wooded habitats. Trees in highly developed urban areas are not deemed to be suitable habitats.

To avoid impacting these bats, counties could adopt a policy requiring the removal of trees at least 5 inches dbh between October 1 and March 31, when the bats are hibernating in caves and abandoned mines. According to the U.S. Fish and Wildlife Service, if trees must be removed outside of this time frame, the months of April, August, and September are preferred in order to avoid the times when bat colonies are most dense and young bats cannot fly.

Migratory Bird Treaty Act Compliance

The Migratory Bird Treaty Act prohibits the killing of protected migratory birds without prior authorization by the U.S. Fish and Wildlife Service. The act protects all native North American birds and their nests, which includes over 1,000 species. Before roadside vegetation management is implemented, precautions should be taken to prevent the disturbance of active nests (those with eggs). Active nests will most likely be present from April 1 to July 15.

Chemical Methods for Brush Control

Chemical Methods for Brush Control thompsbbHistory

The era of using chemical methods for controlling roadside brush began in 1945 with the commercial availability of 2,4-D. These early days of roadside vegetation management consisted of blanket spraying of herbicides across vast swaths of roadside vegetation. However, because this method did not attempt to target only specific unwanted brush species, it also killed desirable vegetation. Without long-lived perennial vegetation competing with undesired vegetation, annual weeds and short-lived perennials grew and dominated roadside ditches. Additionally, early herbicides, such as Agent Orange, were also associated with increased risk for various types of cancer.

From the late 1980s until now, many Iowa counties have adopted IRVM principles to manage their roadsides. In the 2000s, cities also began to practice IRVM. Because the blanket spraying techniques described above were ineffective and potentially unsafe, IRVM emphasized strategic spraying to manage weeds and brush.

Timing of Strategic Herbicide Application

Some programs do not cut or mow in areas where herbicide is applied to allow time for the chemicals to completely kill the treated shrubs and trees. Regardless of the application method used, treating woody vegetation when it is young is more cost-effective and takes less time than using mechanical equipment to remove large trees and shrubs. Killing trees when they are young and small also prevents residents from becoming attached to the trees and objecting to their removal.

Worker Safety Around Chemicals

Though not part of a brush control strategy, pesticides are another chemical that may occasionally be used in some IRVM plans. Roadside managers should be aware of worker safety concerns related to herbicides and pesticides. Federal and state laws require that people using pesticides on public property, such as the right-of-way, be certified as pesticide applicators. For information on pesticide applicator certification, consult the Iowa Department of Agriculture and Land Stewardship.

Safety Tips When Applying Chemicals

- Always read the label; this is critical to ensure you use the product correctly and take appropriate precautions.

- Follow these personal protective equipment tips:

- Wear clothes such as a long-sleeved shirt, long pants, closed-toe and nonporous shoes, and chemical-resistant coveralls.

- Wear safety goggles or glasses to protect your eyes.

- Wear a cap or hard hat to protect your head.

- Wear heavy rubber (not cloth) chemical-resistant gloves.

- Tuck the gloves inside your shirt sleeves.

- If the label indicates they are safe to reuse, wash gloves with soap and water after every use.

- Disposable latex gloves can be used, but must be discarded after every use.

Sensitive Areas

Consider using non-chemical methods such as mowing, burning, and planting competitive native species to control woody vegetation in the following areas that are easily affected by chemical herbicides:

- row crops

- organic farms

- windbreaks

- bee habitat, including nearby flower sources

- flower and vegetable gardens

- landscape trees

- residences, especially those housing people with lung conditions such as asthma or COPD or habitants with pets

- prairie remnants and reconstructed prairies

- decorative flowers planted in the ditch by residents

- trails in the right-of-way

- waterways

If it is determined that herbicides must be used, communicate with landowners who may be affected and take extra care to avoid chemical drifting.

Pesticide applicators must follow what is known as Iowa’s “Bee Rule,” Iowa Administrative Code Chapter 45 21–45.31(206). Under this rule, commercial pesticide applicators cannot use pesticides labeled as toxic to bees for blooming crops within one mile of a registered apiary (a collection of beehives) between 8 a.m. and 6 p.m. Beekeepers can take legal action if they believe their site has been affected by pesticide spray.

Pesticide applicators must also avoid spraying near organic farms, as drifting onto the farm could lead to decertification of the farm’s organic status. For the farm to be certified organic, it must be chemical-free for three years.

Pesticide applicators can identify sensitive areas, including organic farms and apiaries, by checking the Iowa DriftWatch map, which is available as a website and on the FieldCheck by FieldWatch mobile app. Applicators can register by email if they want to be notified when new sites are added near a given location.

Some counties have a no-spray program, where landowners adjacent to county roadsides may request that they not be sprayed. The landowner must agree to remove noxious weeds using non-chemical methods. Consult with the county engineer for details about local policies.

Foliar Spray Treatment

Foliar spray is used on growing plant leaves, stems, trees, and shrubs shorter than 10 feet tall and too numerous or small to cut efficiently. The herbicide absorbed through the leaves and stems moves through the plant, killing the growing parts and preventing regrowth. The lower canopies make it easier to completely cover the shrubs and trees with herbicide. However, it is not recommended for taller trees because it can be more difficult to obtain full coverage on them, and spray drift into nontarget areas is more likely.

Foliar spray is applied during the growing season from May to October to increase maximum absorption. Use extra caution to avoid spray drift onto private property or the vicinity of a waterway such as a creek, river, or drainage way. If spray drift is a concern in sensitive areas, consider using basal bark spray or cut stump treatment instead.

Low-Volume Foliar Spray

Applicators use handheld or backpack sprayers to treat tree foliage with a fine coating of herbicide. This method improves precision, saves money on chemicals, and reduces damage to nontarget vegetation. This method is more appropriate for smaller areas of vegetation than high-volume foliar spray.

High-Volume Foliar Spray

Applicators use mechanically powered equipment, such as truck-mounted sprayers with high-pressure nozzles, to treat the foliage of target shrubs and trees using 25–200 gallons or more of herbicide per acre. This method can be appropriate for large areas of dense vegetation.

Some more commonly used herbicides for foliar spray include triclopyr, triclopyr choline, metsulfuron-methyl, aminopyralid, and aminocyclopyrachlor. Before mixing herbicides, check the labels for proper instructions.

Frill Treatment

Also known as “hack-and-squirt,” this method of controlling invasive trees involves cutting the bark at least one inch deep to create frill cuts where herbicide can be applied to the cambium (the tissue layer that is the growing part of the trunk). Frill treatment is appropriate for large trees or trees at least one inch in diameter, where foliar spray is not feasible because of hard-to-reach brush and trees or nearby sensitive areas. The best time of year to use frill treatment depends on the herbicide; some can be applied at any time of the year, while others are applied only during periods of active growth. Spring, when sap flow is heavy, is typically avoided because the sap can reduce herbicide effectiveness.

To execute a frill treatment, cut the tree below the last live branch. Use a hatchet or other sharp blade to make downward cuts or frills at a 45-degree angle around the tree trunk to reach the cambium layer (the layer of cells that produces new wood and bark). Space the cuts evenly around the trunk, leaving spaces between them so the herbicide can move throughout the tree. For larger trees, a one-inch space between cuts is recommended.

The cuts should be immediately filled with herbicide from a spray bottle or backpack sprayer. The chemical is absorbed into the tree’s vascular system and transported throughout the tree, resulting in its death. Water-soluble herbicides like clopyralid, glyphosate, imazapyr, and triclopyr may be used. Read the label to ensure the product is approved for frill treatment.

Waiting at least a month after treatment before removing the tree ensures the herbicide reaches all parts of the tree and completely kills it. After the tree is dead, it can be felled using appropriate tree-felling techniques.

Basal Bark Spray Treatment

This efficient, targeted method involves spraying herbicide on live bark near the base of a plant. The bark does not need to be cut. An oil carrier in the herbicide solution facilitates penetration through the bark into the plant.

This method is more likely to be used within native plantings and areas that cannot be cut with equipment, such as brush in fencelines. Basal bark spraying is effective on shrubs and trees 2 inches or less in diameter at the base of the tree because the bark of these younger trees is thin enough for the herbicide to penetrate. The bark should be sprayed 12–18 inches above where the shrub or tree meets the ground. Using a dye to mark treated stems may assist in tracking which plants have been treated. A penetrating oil should be added if it is not included in the herbicide mix. Check the label for the recommended ratio of chemical to oil. Basal bark spray treatment is a slow process because trees must be treated carefully to avoid affecting nearby vegetation. It can take several weeks to see signs of herbicide impact. Depending on the species, it may take several months for the plant to completely die.

As with frill treatment, the best time of year for basal bark spray depends on the herbicide used. Some IRVM plans say the best treatment window is between November and March. If there is so much snow on the ground that you cannot reach the base of the tree, it is not a good time for basal bark treatment. Times of heavy sap flow should also be avoided. Spraying when the weather forecast calls for dry conditions for four days can prevent rain from washing the herbicide into adjacent vegetation, which could create a “ring of death” of dead vegetation around the base of the tree that has been sprayed.

The applicator uses a backpack or handheld sprayer to spray herbicide on the stems of target trees. The spray is applied around the entire circumference of the tree to the lower part of the trunk, 12–18 inches off the ground, where the bark is thinner. After the herbicide is absorbed, it moves throughout the plant and kills it.

Examples of herbicides used in basal bark spray include triclopyr, triclopyr + 2,4-D, aminopyralid, aminocyclopyrachlor, and imazapyr. Check the labels for proper instructions.

Cut Stump Treatment

For this method, vegetation must first be cut at the stump to within 3–4 inches of the ground and then treated with herbicide, which enters the cambium and moves into the roots. Cut stump treatment quickly targets and kills the root systems of trees or shrubs. Stumps that are not treated with herbicide will typically resprout. Cut stump treatment is also used for woody vegetation that is larger than 6 inches in diameter is too large for basal bark spraying. Treatment can be done at any time of year when the sap is not flowing, but many roadside managers prefer October through early March for the best results.

Use a chainsaw or other equipment to cut the tree as level to the ground as possible so the stump will not affect any vehicles entering the area. Treat the exposed stump within a few minutes of cutting. Otherwise, the stump can seal itself off and prevent the herbicide from penetrating. Applying herbicide immediately also avoids missing stumps. Apply the herbicide directly to the lighter-colored greenish cambium tissue layer on the stump's outer edge.

Triclopyr and glyphosate products can be used in sensitive areas because they are relatively nontoxic to aquatic wildlife and leach slowly through the soil. Picloram, potassium salt of aminocyclopyrachlor, and aminopyralid can be used in other areas; they are not appropriate for sensitive areas because of their greater toxicity in aquatic environments and ability to stay in the soil for many months. Potassium salt of aminocyclopyrachlor and aminopyralid can effectively treat species that are tougher to kill. Use herbicides labeled as safe to use near waterways when treating brush adjacent to sensitive aquatic areas.

Mechanical Methods for Brush Control

Mechanical Methods for Brush Control thompsbbMechanical methods are the most appropriate for controlling woody vegetation on a large scale. If trees or brush on private property need to be cut as part of the plan for a particular site, existing policy on brush removal from private property should be followed, and a signed written agreement should be obtained before the work is performed. See Appendix 8B for an example log disposal policy used by Fayette County Road Department.

Equipment

Excavator

While excavators are often used to move large amounts of earth and rock, they can also be used to clear trees and brush. The excavator operator can use the large bucket attached to the hydraulic arm to dig around the root ball of a tree to grab it and pull it out of the ground. This method of permanently removing the plant is known as “grubbing.” A disadvantage of grubbing is the soil disturbance it causes, which can result in erosion and the growth of invasive weeds unless the site is reseeded with vegetation. The cost of reseeding should be considered. Alternatively, to minimize soil disturbance, the cut stump treatment can be applied.

For smaller brush, the excavator bucket teeth can be used to rake woody debris into piles. Contracting with a skilled excavator operator can facilitate the efficient clearance of large trees and brush.

Bulldozer

Bulldozers can be used to push over trees with their large blades. Invasive species may invade the bare ground left in areas treated by bulldozers unless the ground is reseeded.

With both excavators and bulldozers, it is important to have skilled operators who know how to properly fell a tree so it does not damage equipment or injure people.

Bucket Truck

A bucket truck can lift roadside managers into the tree and shrub canopy in areas where steeper grades limit access by foot. It can also be used when branches on tall trees overhanging the road need to be managed. While in the bucket, staff may trim branches with a chainsaw or pole pruner.

For safety, employees should wear a fall restraint safety belt system or a full-body harness fall arrest system that tethers the worker to the lift. Follow Occupational Safety and Health Administration guidelines (1910.333(c)(3)(i)) that call for remaining a safe distance from power lines.

Boom Mower

A boom mower attaches to a tractor or loader and can be used to cut brush, small trees, and grass in areas that are difficult to reach, such as behind guardrails and down steep slopes. The hydraulically operated arm can be raised, lowered, and angled as needed.

Forestry Heads

A forestry head is a cutting head that can be attached to a skid steer, tractor, excavator, or bulldozer. Forestry mulchers are a type of forestry head that uses a rotating drum or blades to cut and grind woody vegetation, turning it into mulch. Depending on the model, forestry heads are designed to mulch much larger vegetation. They can cut and mulch trees up to 15 inches in diameter and mulch smaller trees up to 8 inches in diameter. However, some species are more stringy and difficult to cut and mulch with a forestry head (e.g., elm and hackberry).

Forestry heads can be used to remove brush and grind stumps. They are more powerful than handheld brush cutters (see Brush Cutters below) and more suitable for clearing dense brush and trees. Forestry mowers, another type of forestry head, can typically handle woody vegetation up to 8 inches in diameter, although some models can cut larger vegetation.

There are two types of forestry mowers, rotary and drum, which are described separately below. The necessary maintenance is minimal for both, consisting of greasing and rotating the blades or cutting teeth. Carbide cutting teeth last longer than blade systems and may be preferred unless shrubs are the primary vegetation being cut. Some roadside managers have noticed that the teeth can last a long time if they are kept high enough during the cutting process so that they do not get too dirty with soil, and if the teeth are cleaned regularly.

Rotary Forestry Mowers

These mowers employ a spinning set of blades or teeth on a rotating drum to cut and shred vegetation. They can clear more acres in a day than drum forestry mulchers. However, rotary-style mowers may throw large chunks of mulch onto the road, which can be dangerous if left there. Chunks may also be thrown into adjacent farmers’ fields, which can impact farming efforts and upset the farmers. Roadside managers should set aside time after mowing with rotary forestry mowers to pick up any flung chunks.

Drum Forestry Mowers

These mowers use a cylindrical drum with multiple cutting teeth that rotate vertically to mulch material. They are slower than rotary forestry mowers but leave behind a cleaner work area by producing smaller chips that are not thrown as far as the chunks produced by rotary forestry mowers. Drum heads are also better at grinding stumps, including large stumps, into chips by going over them multiple times. The drum can then be put into the ground to incorporate the chips into the soil.

Tree Shear

A tree shear can be placed on a smaller piece of equipment than a forestry head. Often mounted on skid steers, these attachments shear trees with a pair of blades, which is effective for cleanly cutting small-diameter trees while producing minimal debris. Because of their precision, tree shears can be useful for selective tree removal. Depending on the species, some trees removed this way may regrow, and the stumps may need to be treated with herbicides.

Wood Chipper/Tree Shredder

A wood chipper, also known as a “tree shredder,” cuts branches into smaller wood chips for mulch or compost, making it easier to transport tree waste to the landfill or public works department. Similarly, a tree shredder processes smaller plant material, such as small branches and twigs. When it comes to these two machines, it is more common for roadside managers to use wood chippers. The woody vegetation that goes into wood chippers or tree shredders is cut down using equipment such as loppers, bow saws, chainsaws, or forestry mowers. The type of equipment needed will depend on the size of the shrub or tree. Roadside managers then feed the branches into the wood chipper. For trimming small woody roadside vegetation, a wood chipper with a capacity of 9 to 12 inches will probably be sufficient. A chipper with a capacity of 15 to 19 inches is better for large trees. Check with an equipment dealer to ensure you get the right capacity for your needs.

Diesel wood chippers typically cost more than gas wood chippers, but usually use less fuel, are more powerful, and can handle larger branches. While diesel wood chippers may be more durable than gas wood chippers, they also have a more complex design and may require more maintenance.

Another choice to make when buying a wood chipper is whether to buy one with a drum or a disc. Drum chippers use a rotating drum with knives, while disc chippers use a disc with blades. Drum chippers can quickly process large amounts of wood. Disc chippers are better at producing more uniformly sized chips. With their larger size and greater power, drum chippers typically cost more than disc chippers.

Wood chippers can be towed behind a dump trailer or box-bed truck. This allows for chipping and mulching directly into the truck bed and easy dumping of the mulch afterward.

A wood chipper winch (a mechanical rotating spool for pulling an object attached to a cable back toward the spool) pulls large and difficult-to-reach branches and limbs up to the chipper, requiring less manual labor from the chipper operator. It is handy when pulling brush from narrow locations that a wood chipper cannot access, such as the roadside. It also makes the work safer, since operators spend less time near the chipper’s feeding mechanism.

Brush Mower

These mowers, also known as “rotary cutters,” use wedge-like blades to cut through thick vegetation, such as small trees and bush, and are effective for clearing large, overgrown areas. Tow-behind brush mowers can be used with ATVs, UTVs, or lawn tractors. Brush mowers can throw roadside debris, such as metal cans, at high velocities toward the road and the mower operator. To reduce this safety risk, check chains (also known as “deflector chains” or “rock guards”) or heavy mesh screens can be installed on the front and back to deflect or slow down debris.

Brush mowers are also available as large, heavy, and powerful walk-behind lawnmowers. They use a heavy blade to cut through woody brush and saplings. Some units must be pushed, while others are self-propelled, so the user only has to steer. Brush mowers are helpful for small patches of brush.

Tow-behind and walk-behind brush mowers are available in electric- or gas-powered versions. Electric-powered brush mowers have a lower noise level, lower emissions, are easier to maintain, and weigh less. Gas-powered brush mowers have more power and are better for cutting through thick vegetation. Gas-powered brush mowers are more flexibly mobile since they do not rely on a power cord or battery.

Brush Cutter

Brush cutters (also known as “weed eaters” or “clearing saws”) are handheld metal blades with multiple cutting edges or thick nylon cords attached to a spinning head. They cut thick weeds, small saplings, and light brush by chopping them as the head moves through the plants. They are easy to operate and effective on smaller woody vegetation. Unlike mowers, brush cutters cut and trim, leaving behind debris instead of mulch.

Chainsaws

Chainsaws are available in many sizes and at various prices. They are used to fell trees, prune branches, and cut logs into smaller pieces. The chainsaw bar length should be at least two inches longer than the diameter of the vegetation being cut. Branches should be pruned following the American National Standards Institute A300 Tree Care Standards.

When using a chainsaw to fell a tree, cut the stumps to within 3–4 inches of the ground. Treating stumps with herbicide after cutting with the cut stump treatment approach described previously prevents the stump from producing sprouts.

When using a chainsaw at a work site, it can be helpful to have a toolbox with sharpening tools, extra chains, screnches (a tool combining a wrench and a screwdriver), wedges, and other tools needed to fix saws or aid in the felling process.

Manual Methods for Brush Control

Manual Methods for Brush Control thompsbbLoppers

A type of pruning shear with long handles and fixed blades, loppers are used to cut branches or stems that are 0.5–1 inch in diameter. They are very portable and useful for pruning shrubs and trees or cutting the trunks of small groupings of trees and shrubs.

Handling of Cut Brush

Handling of Cut Brush thompsbbBurning

Under Iowa Administrative Code 567—23.2(455B), open burning is generally prohibited. However, the following exceptions pertaining to the disposal of woody vegetation that has been removed from roadsides may allow for the burning of cut brush.

At a municipal burn site, trees and tree trimming not originating on the premises may be burned provided that:

- the site is operated by a local government entity

- the site is fenced and access is controlled

- burning is supervised and conducted regularly

- burning is conducted when conditions are favorable to the surrounding property

- unless a written waiver is obtained, the burn site is limited to areas at least 1/4 mile from any inhabited buildings

Before burning for the first time, check with the relevant city or county department since local rules may be more prohibitive than state ordinances. Some counties require obtaining a permit before burning. When burn bans are in place, most open burning is not allowed.

Chipping

Brush that is chipped into mulch may be collected and trucked to county locations, such as a secondary road department shop yard.

Leaving Alone

Some brush may be left to provide wildlife habitat on site as it naturally deteriorates. Small mammals such as squirrels, foxes, and chipmunks may use brush piles as shelter. Songbirds may use brush piles for shelter and as a source of nesting material.

Protecting Worker and Motorist Safety in Work Zones

Protecting Worker and Motorist Safety in Work Zones thompsbb

During active brush control work, equipment on the side of the road may distract drivers. Roadside managers need to plan how they will keep workers and motorists safe. Refer to the Manual on Uniform Traffic Control Devices for Streets and Highways for more detailed information on safely diverting traffic from a work area.

The following recommendations for conducting safe roadside brush control with equipment in the roadside are excerpted from “Tree and Brush Control For County Road Right-of-Way.”

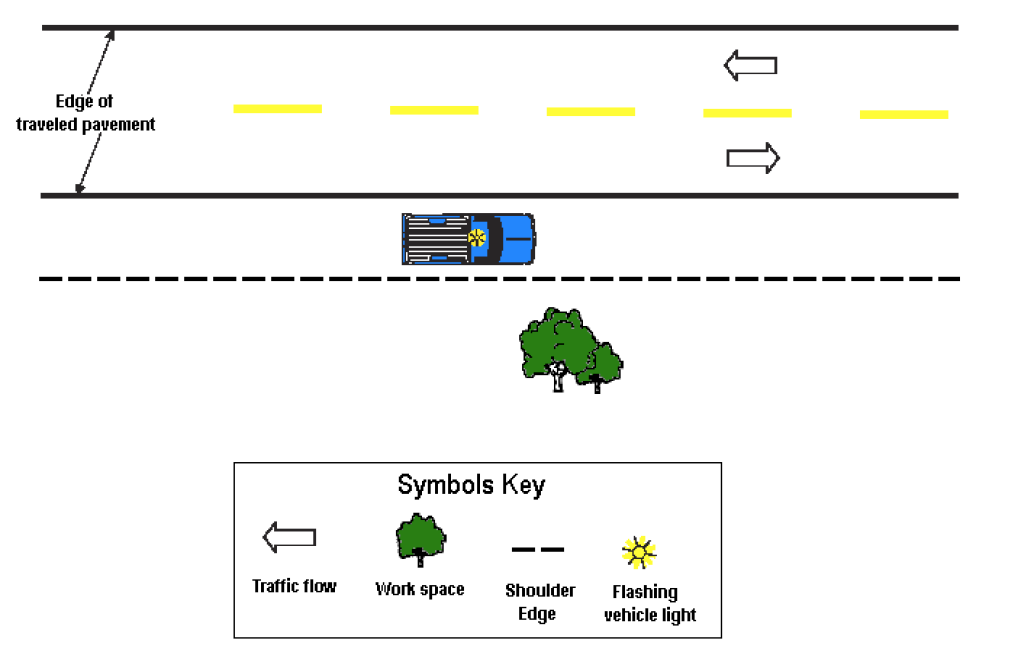

Short-Term Roadside Work With No Encroachment on the Roadway

- Workers and equipment operate within 15 feet of the edge of the traveled way for up to one hour (see below for work lasting more than one hour).

- Whenever appropriate, vehicles should be parked in entrances and driveways. If that is not possible, vehicles should be parked on the shoulder as far from open traffic lanes as possible.

- Vehicles should be equipped with a yellow revolving light or yellow strobe light.

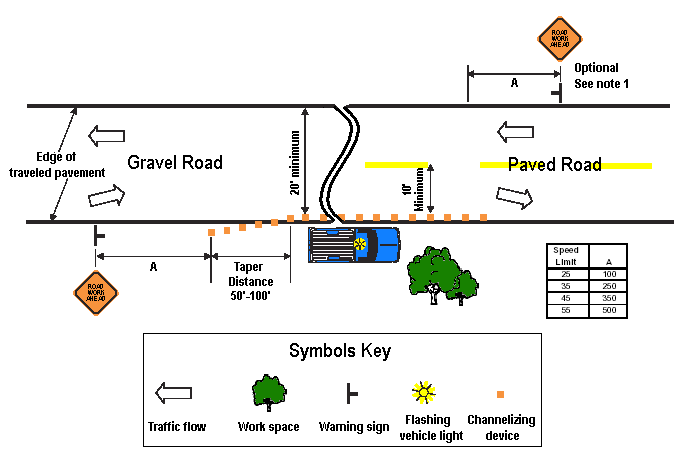

Lengthier Work and/or Minor Encroachment of a Work Zone Onto a Two-Lane Road

- This work can occur on either gravel or paved roads.

- The work could include chainsaw work, cut stump treatment, chipper work, foliar spraying, and basal bark spraying.

- Signage is required in the opposite lane of traffic only when sight distance is restricted.

- Traffic control via flaggers is not required if bidirectional traffic can move freely through the work area at a reduced speed.

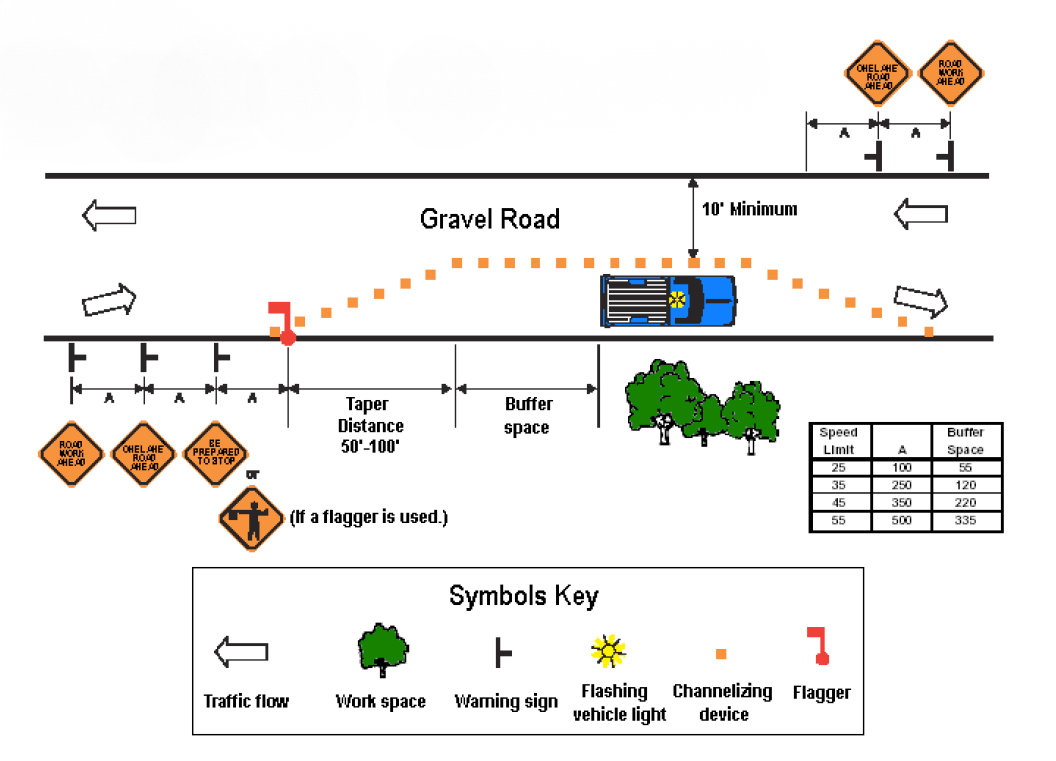

Major Encroachment and/or Lane Closure on a Gravel Road With Self-Regulating Traffic

- The work could involve the use of aerial lift trucks, tractors with boom mowers, excavators with brush cutters, tree shears, a bucket and thumb, and other heavy equipment.

- Diagram how lanes of the road would be closed for the brush control project during daylight hours.

- Traffic volume must be less than 2,000 vehicles per day.

- Work vehicles should not be parked on the opposite shoulder within 500 feet of the work area.

- Traffic in the open lane should be allowed to flow freely.

- Cone spacing should be based on the posted speed limit.

- Traffic control via flaggers should be required if:

- visibility is less than a quarter mile

- workers are on the road or close enough to the road that they need to be protected from traffic

- traffic flow is more than 15 vehicles per 15 minutes

- When access to the truck is necessary and the side being accessed is exposed to traffic, a 2-foot safety zone is required between the cones and the truck.

- Open lanes should be at least 10 feet wide. If a lane is 9 feet wide, it may remain open for short-term use if traffic is low in speed and volume and does not include long, heavy commercial vehicles. The lane should be closed if it is less than 9 feet wide.

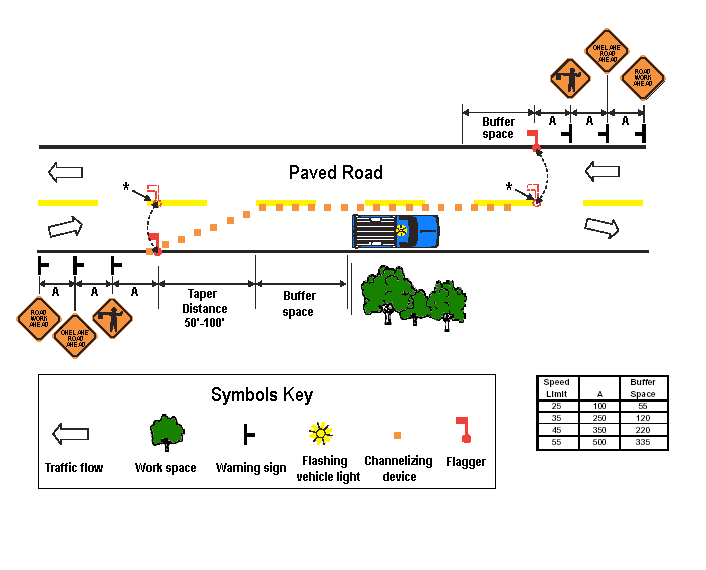

One Lane Closed of a Two-Lane Road for Less Than a Quarter Mile Long

- The work taking place could include extensive brush clearing, the use of excavators with brush cutters, tree shears, a bucket and thumb, and other heavy equipment.

- The work should take place during daylight hours only.

- Work vehicles should not be parked on the opposite shoulder within 500 feet of the work area.

- Cone placement guidelines:

- Space the cones 10 to 20 feet apart to create a taper that gradually narrows the amount of the road available to traffic.

- A minimum of five cones are to be used in a taper.

- Cones that are part of a taper around a curve should be placed at the following intervals:

- every 20 feet where the horizontal curve radius (a measure of the bend in the road) is less than 300 feet

- a minimum of every 50 feet where the horizontal curve radius is 300–1,000 feet

- every 120 feet when the speed limit is 60 miles per hour or above

- Individual cones that would interfere with the work may be omitted during work hours, except for cones in the taper, which are required at all times

- Traffic control flagger guidelines:

- The flagger should stop the first vehicle from the position shown in Figure 8.4 and then cross traffic to the other lane to stop other vehicles.

- Additional flaggers should be stationed at intersections or crossings within the work area to prevent vehicles from entering against the flow of traffic.

- For a short time, the length of the work area may change as much as half a mile to improve the flagger’s sight distance. For example, the work area and flagger’s sight distance may need to be adjusted to account for changing visibility conditions due to weather or the amount of daylight.

Prescribed Burns

Prescribed Burns thompsbbPrescribed burns can prevent shrubs that invaded native prairie plantings from getting too big. To conduct prescribed burns, cities and counties should have staff who have completed wildland fire training (training courses S-130 and S-190). See Chapter 9: Prescribed Burning for more information.

Roadside Real Talk

Insights from Roadside Managers and Other Professionals

Fall prescribed fire works very well for controlling small-to-medium eastern red cedar, especially if done following earlier foliar spraying to help stress the tree.

—Lakota Kirst, Cerro Gordo County, 2024