Chapter 6: Erosion Control

Chapter 6: Erosion Control thompsbb

Controlling erosion protects water quality, maintains the structural integrity of the roadway, protects germinating native seed, and helps counties and cities comply with National Pollutant Discharge Elimination System (NPDES) Phase II regulations. It is among the most important goals of an integrated roadside vegetation management (IRVM) program. Permanent vegetation is the long-term solution to eliminate erosion, but short-term erosion control is necessary to protect exposed soil while vegetation matures.

Types of Erosion

Types of Erosion thompsbb

The following types of soil erosion are of greatest concern for roadside managers.

Occurring on Slopes

Splash Erosion

Raindrops dislodge exposed soil particles, causing erosion. These particles settle in soil pores and, when dry, form a crust, reducing infiltration during subsequent rains.

Sheet Erosion

This type of erosion occurs in heavier rains on uniformly smooth soil surfaces. The raindrops carry soil particles away in a shallow sheet of water.

Rill Erosion

Slight differences in soil surface elevation cause runoff to concentrate and form a pattern of cuts or rills. This type of erosion is more likely to occur than sheet erosion since slopes are rarely uniformly smooth.

Occurring in Concentrated Flow Areas

Channel Erosion

This type of erosion is due to the force of flowing water. Many, if not all, roadsides are conduits for this kind of concentrated stress on the soil.

Planning for Erosion Control

Planning for Erosion Control thompsbbErosion control objectives should be considered in the planning stage of every roadside vegetation project. Many factors affect a site’s erosion potential. Some of those same factors also affect how quickly vegetation will establish and provide stabilization. The following interconnected factors should be analyzed to determine what, if any, erosion control practices are necessary:

- time of year (How long will the soil be exposed?)

- soil type and fertility

- slope length, grade, and aspect

- potential for off-site surface water to flow into the project area

- type of seed mix (e.g., warm-season seed establishes slower than cool-season seed)

- weather forecast

- the consequences of failure, which may include weakening the stability of the road or infrastructure such as culverts

- the presence of sensitive areas (e.g., wetlands, sensitive waterways, and critical habitats for threatened and endangered species that may be negatively affected by an influx of soil and pollutants associated with erosion).

Erosion Control and IRVM

Some IRVM programs will be more involved in erosion control than others. Sediment control and long-term erosion control may be the responsibility of other county or city departments or a hired contractor.

However, at a minimum, all IRVM programs are responsible for short-term soil protection through proper site preparation and use of nurse crops, stabilizer crops, and mulches.

Erosion Control Techniques

Erosion Control Techniques thompsbbGeneral short- and long-term erosion control techniques are outlined below. At the end of this chapter, there is a list of useful erosion control industry websites with up-to-date technical specifications and guidelines. Take advantage of these resources and other educational opportunities to stay well-informed about this rapidly evolving industry.

Soil Preparation

Strike a balance between striving for an ideal seedbed and maximum erosion control. Firm, friable soil surfaces—recommended for seeding—can be susceptible to erosion. Loose, rough soil surfaces slow runoff and provide better infiltration. Surface roughening practices, such as directional tracking and grooving, slow runoff by creating depressions or grooves perpendicular to the water flow. On steep slopes, these practices must be used with other methods, preferably hydroseeding, described in detail below.

Directional Tracking

Driving a bulldozer or other tracked vehicle up and down a slope leaves depressions perpendicular to the slope (Caution: Driving a tracked vehicle across the slope can increase erosion). Tracking may not be appropriate on clayey soil since compaction can inhibit vegetation establishment. Severe compaction can even prevent no-till drills from penetrating the soil. Concerns regarding compaction decrease when hydroseeding or broadcasting during the dormant season since freezing and thawing loosens the soil.

Grooving

Pulling a disc or ripper behind a tractor or dozer or back-dragging a toothed bucket with a loader across a slope creates a series of ridges and grooves. If these particular grooving approaches are not feasible, other implements that a department has can be used. Grooving can be more effective than tracking because the depressions are usually deeper and the soil is left looser.

Statewide Urban Design and Specifications (SUDAS) specifies that grooves should be no more than 15 inches apart and 3 inches deep, though groove depth is subject to differing opinions. Deep grooves improve erosion control but increase the likelihood of seeds being buried too deep to germinate. The seeding method will help determine the appropriate groove depth. One-step hydroseeding calls for deeper grooves since mulch keeps the seed near the surface. If the seed is not incorporated in a slurry when planted, lighter grooving is recommended.

Mulch

Mulch helps prevent splash erosion and holds seeds in place by absorbing rainfall impact and binding soil particles together. Mulching is accomplished by applying straw or hydromulching (i.e., spraying a slurry comprised of water, seed, mulch, dye, and optional fertilizer).

Straw

Dry cereal straw—free of noxious weed seed—can be applied alone or on top of the seed to provide short-term erosion protection, conserve moisture, and suppress weeds. Oat or wheat straw is typically used at a rate of 1–1.5 tons per acre. Straw applied evenly at the correct rate will allow approximately 50% of the soil to be visible. If applied too heavily, seed germination may be affected. It is better to use longer mulch, and some bale processors can be adjusted to apply mulch in this way.

Straw mulch must be crimped or tacked (using a binding agent) in place to keep it on-site; otherwise, it is prone to blowing away on windy days. Roadsides that can be driven on can be crimped. Crimpers (also known as “mulch tuckers” or “mulch discs”) are mounted on a 3-point hitch and pulled with a front-wheel assist tractor. Test runs are necessary to ensure the crimper wheels go into the soil at least three inches—enough to anchor the straw. Properly anchored straw mulch will stand straight and look like oats mowed high.

Tacking is accomplished by adding tackifier to water in a hydroseeder. Tackifier rates vary depending on the brand. Rates are provided on the bottle in pounds per acre. If too much tackifier is added, the mixture will get slimy, preventing the pump from priming. The tackifier solution should be applied evenly on top of the straw until the straw is wet but not running off. The solution will dry and act as an adhesive to hold the straw in place.

Some IRVM programs use prairie hay harvested from plots or straw mulch plantings. The application method is similar to that for straw, though tackifier rates may vary depending on the dominant species in the hay and how likely it is to blow away. Fewer bales will be necessary because hay weighs more than straw.

Roadside Real Talk

Insights From Roadside Managers and Other Professionals

We use wheat straw. It seems to be longer than oat straw and is typically the same price. I have worked with a local contractor who brings up Kansas wheat straw. We have also used Iowa certified weed seed-free straw. We use an agricultural-type bale processor (no cannon). I use the rate of one-and-a-half tons per acre 1.5 T/acre as a minimum when planning. Just be sure you aren’t blanketing over your seed. You should be able to barely see the ground through the mulch before it is crimped. Tractor, bale processor, and crimper are the equipment I have found most helpful for erosion control. Dollar for dollar, straw mulch is the best money spent on erosion control.

—Wes Gibbs, Jones County, 2024

With oats or wheat straw, I’ve used seed-bearing stalks to my advantage; it can work as a good cover crop. To apply straw mulch, I use a small bale blower with a gas motor. It does a nice job of shredding up the bales. The process is labor intensive, so I usually only tackle small projects with it. The big round bale blowers/shredders, I don’t have one, are less labor intensive and can cover a lot more area in less time. This method requires mobilization for the bales and a large tractor to run it. I generally mulch at 1,000 to 1,500 pounds per acre. If harvested in the fall just after the seed heads have matured, prairie hay bales will carry enough seed to plant a new site. Some seed supplements may need to be used. I think prairie hay works better than straw. It is just reedy enough that it lays out and kind of locks together. Straw is a lot lighter and doesn’t lay down as well.

—Ben Hoskinson, Mahaska County, 2024

Our mulch tucker/cultipacker combo is 8 feet wide and weighs 1,600 pounds. We pull it with a 95 horsepower tractor—you might be able to go a little smaller as long as you have sufficient weight in front to balance it when in the “up” position.

—Wes Gibbs, Jones County, 2024

We always use one-and-a-half tons per acre of straw mulch.

—Ole Skaar, Roadside Development, Iowa Department of Transportation, 2011

We have a couple of organic farmers in the county. When I need straw, I buy it from them. They usually have a field in their rotational plan that will be in oats. I support the concept and like to help them in this small way.

—Linn Reece, Hardin County, 2011

Hydroseeding

Hydroseeding is a planting method that uses a hydroseeder to spray bare soil with a slurry of water, mulch, tackifier, fertilizer (optional), soil amendments (e.g., plant growth stimulant such as microbial inoculant), and seed. See Chapter 5: Seeding for information on how to conduct a successful hydroseeding project.

Hydromulch

Hydromulching combines water, seed, mulch, dye, and optional fertilizer in a slurry. Hydromulch conserves soil moisture and can prevent splash, sheet, or rill erosion. However, hydromulch is not suitable to withstand the shear stress experienced in areas with concentrated flow that causes channel erosion. See Chapter 5: Seeding for additional information on hydromulching as it relates to seeding efforts.

Hydromulching Rates

Hydromulching rates vary by mulch brand. An example mixing rate for hydromulch is 500 pounds of mulch for 1,200 gallons of water. However, this rate can be adjusted depending on the brand of mulch used. Thicker mulches can be applied at a lower ratio. Do not exceed rates recommended on the product label. Rates also vary depending on the equipment being used. Getting the right rate is often a trial-and-error process, but these suggested rates are a good place to start:

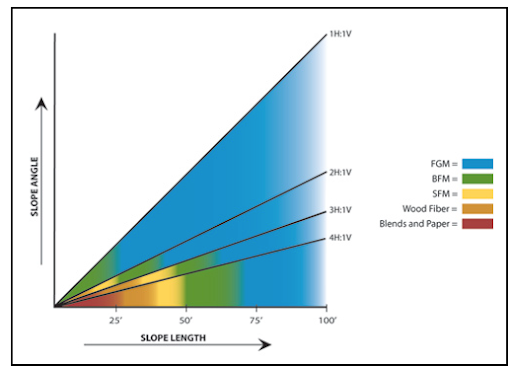

Figure 6.1. Recommendations for hydromulch type to use for erosion control based on slope inclination and length. Reprinted from “Performance Based Classification System for Hydraulically Applied Erosion Control Materials” by F. J. Lauro & M. S. Theisen, n.d., Land and Water, from landandwater.com/features/vol50no6/vol50no6_1.html. 1,000 lbs./acre—a token amount to help carry the seed and show what area has been seeded

- 2,000 lbs./acre—appropriate for most 3:1 slopes

- 3,000 lbs./acre—a very heavy rate for long, steep slopes

Common Types of Hydromulch

As slope length and gradient of the roadside increase, water travels faster, resulting in more erosion. Certain types of hydromulch provide greater erosion control. See Figure 1 for a graphic recommendation of hydromulch by slope length and angle.

Cellulose (Paper)

Cellulose, made from recycled newspapers, magazines, and corrugated cardboard, is the least expensive hydromulch. Its advantages include: greater water retention, quicker mixing, and better pumpability. Cellulose may be the least effective at controlling erosion since it does not have long, interlocking fibers. Avoid applying cellulose too heavily or with too much tackifier (known as the “paper mache effect”), which reduces moisture and airflow to seed. Additionally, some roadside managers have observed that native plants do not grow well when cellulose is used.

Wood Fiber

Wood fiber mulch is produced from milled wood, typically aspen. It is more expensive than cellulose and does not hold as much moisture. However, it has more loft, and the interlocking fibers provide more effective erosion control.

Bonded Fiber Matrix (BFM)

BFM is a wood fiber mulch, usually with elongated fibers, containing various adhesives, binders, and synthetic fibers. It retains its strength much longer than traditional mulches.

Wood Fiber/Cellulose Blend

Blended mulch usually consists of 50–70% wood fiber and 30–50% paper products. It falls in the middle of wood fiber and cellulose mulches in terms of cost, water retention, pumpability, and erosion protection.

Mechanically Bonded Fiber Matrix (MBFM) and Flexible Growth Media (FGM)

These mulches contain elongated wood fibers, crimped synthetic fibers, and various adhesives and binders. The crimped fibers provide a strong, mechanical, fiber-soil bond. The resulting hydromulch slurry does not require any time to go through a curing process to provide erosion protection.

Hydromulch Application

To create hydromulch, mulch is mixed with water and often a tackifier in a truck- or trailer-mounted tank, and the resulting slurry is sprayed onto the site. Tackifiers bind mulch fibers together and bind the mulch fibers to the soil, enhancing erosion protection. Tackifiers are pre-blended in BFM, MBFM, and FGM products and undergo a chemical process known as “cross-linking,” which prevents rainfall from rewetting and dissolving the tackifier after it is applied. Organic and synthetic tackifiers can also be purchased separately to mix with other mulches. See mixing rates recommended by the manufacturer before application.

Though they are often referred to interchangeably, hydroseeding differs from hydromulching, which involves adding mulch to the slurry. Amendments accelerate seed germination and establishment by adding nutrients to soils that are low in nutrients. Amendments include water-soluble fertilizers, water-storing polymers, and plant growth stimulants. Refer to the manufacturer for recommended mixing rates. Peat moss and compost screenings can also be added as a soil amendment, though little research exists on mixing rates.

Synthetic fibers can be added as an amendment to traditional wood fiber and blended mulches to increase their mechanical bond.

Recommended hydromulching rates are shown in Table 6.1. Maximum slopes, benefits, limitations, rates, and longevity considerations for erosion control methods and further discussed in Chapter 5: Seeding.

Roadside Real Talk

Insights From Roadside Managers and Other Professionals

An important factor that can get overlooked when dealing with sheet erosion is the additional overland flow that may be coming from the roadway. This can really affect hydroseeded areas, and increased rates of hydromulch may be needed. This doesn’t seem to be an issue when using blankets—which makes sense since blankets are appropriate for protection against channelized flow.

SUDAS section 7E-5 deals with mulching to prevent sheet erosion, but we feel they are overly cautious. For instance, they don’t recommend hydromulching on slopes steeper than six-to-one. We recommend looking at manufacturer specs for available products.

—Jim Uthe and James Devig, Dallas County, 2024

I use a wood/paper blend, which I think works the best. The wood I’ve used by itself doesn’t have enough substance. I also use FGMs or BFMs as a supplement to the wood/paper or as a stand-alone.

—Ben Hoskinson, Mahaska County, 2011

Compost Blanket

Typically used on nutrient-poor soil, a compost blanket is a 1–4 inch layer of compost made of a blend of coarse and fine materials. If seed is applied with the blanket, the layer should not exceed 2 inches; establishing roots may not penetrate the underlying soil if the blanket is deeper. Be sure the compost is well-cured, meaning it has finished the composting process and has cooled. If the blanket is applied while the compost is still hot, vegetation may not establish.

A compost blanket should not be used where overland flow is expected. While it will safely absorb rainfall, overland flow can erode the compost.

Compost blankets effectively prevent erosion and promote seed growth, but only when applied correctly. Specialized equipment, such as a blower truck, is necessary to apply compost blankets properly, so a contractor is typically hired. Due to the high cost of hiring a contractor, the contract for the job should include a guarantee that the job will be done correctly.

Rolled Erosion Control Products

Rolled erosion control products (RECPs) are arguably the best way to stabilize most areas susceptible to channel erosion. They are also used to stabilize slopes. Because RECPs need vegetation to function properly, site conditions must be conducive to establishing vegetation. In extremely nutrient-poor soils or deep shade, riprap (a layer of large stones) or erosion stone may be the best option. Temporary and permanent RECPs are available. Temporary RECPs prevent erosion while the vegetation matures, after which the temporary RECPs eventually degrade. They are more often used on moderate slopes. Permanent RECPs are applied in areas where vegetation alone will not provide enough erosion control, such as steep slopes and areas with a lot of water runoff.

Manufacturers of RECPs provide specifications for their products online. Most manufacturers also provide software for practitioners that helps them determine the appropriate product for a given site. A database of virtually all RECP manufacturers on the market and their specifications is available in the Geosynthetics Specifier’s Guide.

Types of RECPs

Erosion control blankets (ECBs)

Erosion control blankets are temporary, degradable, rolled products. They are made of natural or polymer fibers that are mechanically, structurally, or chemically bound together to form a continuous matrix.

Netless Blankets

These consist of fibers stitched together with a biodegradable thread. Because there is no net, this product is typically used in frequently mowed areas and areas where animals could become entangled in netted blankets.

Single- and Double-Net Blankets

These consist of one or two polymer or jute nettings interwoven with natural fibers—typically straw, coir (coconut), and/or excelsior. In general, netless and single-net blankets are used on slopes or in low-flow channels. Double-net blankets can be used on slopes and in higher-flow channels.

Turf Reinforcement Mat

Turf reinforcement mats (TRMs) are permanent, non-degradable, rolled products made of synthetic materials. These three-dimensional mats provide immediate erosion protection, enhanced vegetation establishment, and long-term functionality by permanently reinforcing vegetation. TRMs are typically used in high-flow ditch channels and on very steep slopes where unreinforced vegetation may not provide adequate erosion protection.

See the SUDAS Design Manual for the classification of TRMs by material and by their performance in channel and slope applications.

Selecting the Appropriate RECP

Slope Applications

Consulting manufacturers’ general application guidelines (e.g., North American Green) is the easiest way to select an appropriate RECP. Slope length and grade are key selection criteria. When using degradable products, product longevity (determined primarily by material weight) must also be considered. Time of year, soil fertility, aspect (i.e., position of the slope relative to water flow), seed mix, and other factors affect how quickly vegetation establishes. A product may be appropriate for a specific slope length and grade, but if installed over a planting in poor soil, it may deteriorate before vegetation establishment.

Manufacturer software (e.g., North American Green, Profile Products, American Excelsior) is also used to select products for slope protection. Users enter slope length and grade, surface condition of the soil, and the soil erodibility (K) factor for the soil type (found in the NRCS soil survey for each county). The software then suggests multiple appropriate products. Growing conditions and seed mixes determine the appropriate functional longevity.

Channel Applications

When stabilizing a concentrated flow area with temporary RECPs, estimate the amount of flow and time it will take for vegetation to establish. Then use manufacturer specifications to select a blanket with the appropriate strength and longevity.

For large-scale projects, especially in high-flow situations, it may be necessary to conduct the following additional analysis:

- Determine channel dimensions, including the width and grade of the channel bed and slopes on each side of the channel.

- Determine the amount of flow in cubic feet per second (CFS). Flow determination for a given rain event can be done with complex mathematical formulas (performed by engineering staff) or by observing the channel’s watershed and making an educated guess. When protecting channels at culvert outlets, design protection to withstand maximum discharge.

- Consider the consequences of failure to decide whether the project requires protection against a two-year storm, five-year storm, ten-year storm, etc. According to Certified Professional in Erosion and Sediment Control guidelines, when using permanent RECPs (i.e., TRMs), projects are usually designed to withstand the ten-year frequency, 24-hour duration rainfall event. This is about 4 inches of rain in northern Iowa and 5 inches in the southern part of the state.

- Enter channel dimensions and flow into the manufacturers’ software, available on their websites, to determine an appropriate blanket.

Installing RECPs

Erosion Control Blanket Installation

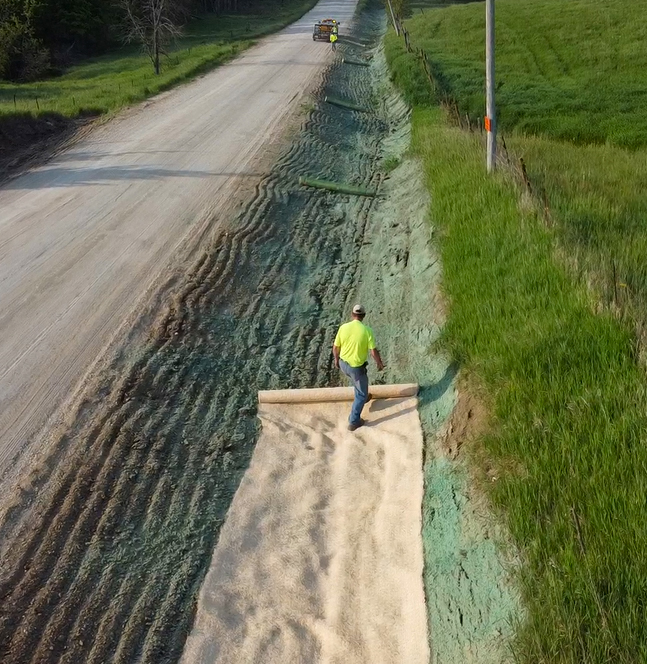

Roadside management staff install an erosion control blanket in Dallas County (photo by Dallas Co. Roadside Technician Jacob Gish). Provide good blanket-to-soil contact by removing debris such as rocks, roots, twigs, and existing vegetation to create a smooth soil surface.

- Trench the top of the blanket to a depth of 6 inches and staple at the bottom of the trench.

- Any overlap between adjacent blankets should be at least 6 inches to prevent gaps between sections.

- Refer to the manufacturer’s specifications for recommended stapling patterns. The area to be protected, often the top of the slope or drainage channel, is used as a reference point and the center point of the blanket is a specified distance, such as 2–3 feet from the reference point. In the absence of recommendations, staple in a staggered pattern using 3-foot centers on a slope and 2-foot centers on a channel.

- In channel applications, center a blanket in the channel bottom to avoid having a seam under the area of maximum flow. At 25–30 feet intervals, place a check strip of staples 2–4 inches apart across the blanket.

- Install additional staples on uneven ground to ensure good soil contact, especially in low points.

RECPs are often maintenance-free after vegetation has been established. Until then, inspect them after every runoff event, adding staples where erosion has occurred. Routine maintenance is easier than repairing and reseeding the large ruts and gullies that can form under improperly installed or maintained RECPs.

Turf Reinforcement Mat (TRM) Installation

- When used in areas that experience weeks-long periods of saturation, provide subsurface drainage to prevent erosion under the mat.

- Anchor mats with 6-inch staples. Use 8-inch staples or stakes in high-flow and loose-soil situations.

- For slope stabilizations, anchor mats with high-performance duckbill or flow transition mat anchors.

- Seed should be drilled or hydroseeded (not broadcast) to prevent small seeds from floating up through holes in the mat and washing away during high-flow events.

- In high-flow situations, BFMs can be used under the mat. Laying sod underneath will provide instant erosion control.

- In slope stabilizations, soil can be placed on top of the mats. In concentrated flow areas, the top layer of soil will wash away unless a straw or erosion control blanket is placed on top.

- TRMs can be infilled with BFMs and FGMs in both channel and slope applications.

Roadside Real Talk

Insights From Roadside Managers and Other Professionals

We had heard at one time that forbs germinate better under straw than erosion control blankets, but we’re starting to become skeptics on that claim. For instance, we just inspected a project where we used an erosion control blanket, and there were just as many partridge pea seedlings in the blanketed areas.

TRMs can stabilize very steep slopes, but in a typical county roadside setting, it may be cheaper to buy more right-of-way, grade it to a general slope, and stabilize it by hydroseeding or seeding/mulching.

—Jim Uthe and James Devig, Dallas County, 2024

If you’re doing a lot of RECP installations, get a staple gun. It’s worth the money! And if you need to cover a lot of surface area, I suggest the 16-foot rolls versus the more common 8-foot rolls). They’re still fairly easy to handle and they cut your installation time and labor almost in half.

—Wes Gibbs, Jones County, 2024

We do not use straw or straw or coir blankets in channels. Those materials don’t absorb water, so the blankets float if rain causes any flow. You might get them to work with sediment logs or lots of staples, but that isn’t cost-effective. Nothing beats good wood erosion control blankets.

—Ole Skaar, Roadside Development, Iowa Department of Transportation, 2011

Other

Flow Transition Mats

Flow transition mats are an environmentally sound alternative for riprap or concrete in the transition area between flow outlets and channel flow. The semi-rigid, plastic mats— approximately 4 feet by 4 feet and a half-inch—have holes that allow vegetation to grow. The mats are installed on top of a TRM in areas of high scour, such as culvert outlets. Flow transition mats can provide better protection than riprap, and installation is an easy, one-person job. Here are some tips for the installation of flow transition maps:

- When placing transition mats on top of the fill, make sure the area is well-compacted to prevent failure from settling.

- Use subsurface drainage in areas that experience long periods of saturation.

- For best results, place sod underneath the TRM.

- If sod is not used, high-flow events could cause erosion before vegetation establishes. To help minimize erosion, install a staple check strip in the TRM directly downstream from the transition mat.

- Check mats after every runoff event during the first two seasons to make sure anchors are still tight.

Roadside Real Talk

Insights From Roadside Managers and Other Professionals

Flow transition mats can be used as a riprap alternative for channel protection if flow occurs only during larger rain events. The channel needs to dry out at times so vegetation can establish.

—Ole Skaar, Roadside Development, Iowa Department of Transportation, 2011

Sediment Control

Sediment Control thompsbbIRVM programs will be responsible for containing eroded soil on the project site. Basic sediment control products likely to be used on county rights-of-way are described below.

Wattles, Sediment Logs, and Filter Socks

Wattles and sediment logs are tubes of straw, coir, or wood fibers encased in burlap or degradable plastic netting and anchored in the ground by wooden stakes. Both filter sediment and slow down water flow. Wattles and logs containing densely packed material—especially straw—are good as slope interrupters. Wood fiber logs are more porous and less likely to float, making them better suited for ditch checks. Both are good for perimeter applications and inlet protection.

Filter socks are degradable tubes filled with compost. They are generally used for perimeter control or at intervals along a slope to capture sheet flow. Polyacrylamide (PAM) may be added to the compost to enhance sediment control. PAM captures clay particles, creating cleaner runoff.

Wattles, sediment logs, and filter socks are usually easy to install and can be put on bare soil or over erosion control blankets.

Silt Fence

Silt fences are geotextile barriers trenched into the ground and supported by posts. They are useful on perimeters and in channels with relatively low flow. As runoff passes through the fabric, silt fences filter out small amounts of sediment. They must be kept clean to function properly and are removed after final stabilization. Silt fences are easy to install and relatively inexpensive.

Silt fences are ineffective in high-volume flow areas and should not be used as check dams, which would be ineffective and can cause more erosion.

Improper installation of silt fences, which is common, renders them ineffective. For proper installation techniques, follow up-to-date specifications.

Check Dams

Check dams should be constructed across the water flow using clean rocks, permeable plastic berms, or similar products. Unlike silt fences, check dams do not cause water to dam up. Instead, they let water pass through, slowing its velocity and dissipating its energy.

Sedimentation can occur on the upstream side of check dams. If sedimentation becomes too heavy, check dams will turn into waterfalls and may be rendered ineffective. Monitor check dams and excavate the upstream side if necessary.

Plastic berms should not be placed in areas where they would be susceptible to filling with debris (e.g., corn stubble from a field waterway). One heavy rain can cause these berms to fill, causing the water to dam up.

Improper design of check dams, which is not uncommon, renders them ineffective. Follow current design specifications and account for the individual characteristics of each site.

Roadside Real Talk

Insights from Roadside Managers and Other Professionals

If a rain event is relatively small, silt fences will function properly as a check dam. But, small rain events typically cause little to no erosion. Silt fences may be good for PR, but they create a point of failure for the project. A roadside is essentially a headwater stream. Stream dynamics show that flow equals the area times the velocity. When the water from a flat, six-foot wide channel is concentrated into a width of typically less than a foot at the low point of a silt fence, the water’s velocity increases substantially, thus erosion is caused instead of prevented.

—Jim Uthe and James Devig, Dallas County, 2024

Rock check dams should mostly be below ground. The waterfall problems can be eliminated if the check doesn’t extend above ground level.

—Wes Gibbs, Jones County, 2024

Additional Erosion and Sediment Control Information

Additional Erosion and Sediment Control Information thompsbb

Soil Characteristics

Manuals

- Erosion and Sediment Control Field Guide

- Iowa Statewide Urban Design and Specifications Design Manual–Chapter 7: Erosion and Sediment Control

Erosion Control Products

- American Excelsior Company

- ASP Enterprises

- EarthGuard®

- ECBVerdyol

- Mat, Inc. Erosion Control Products

- North American Green

- Profile Erosion Control Products

- Quick Supply Co.

- Ramy Turf

- Stormwater Supply

- terrafix®

- Western Excelsior Erosion and Sediment Control Products